You have no items in your shopping cart.

Rollawaycontainer.com srl

Via Luigi Cadorna, 56 - 58

30020 Fossalta di Piave - Venezia (Italia)

Tel. +39 421 67358

Fax +39 421 306462

[email protected]

This website uses cookies to improve users' browsing experience and to gather information on their use of the website. We also use third-party profiling cookies to send advertising messages in line with user preferences. You can learn more and manage your choice at any time by visiting our cookies policy.

|

Rollawaycontainer quality |

| The quality of materials, steel and wheels are Italians, as all the production process. This is our must, because we have always built and always buid our products with the aim of producing a tool that lasts. | ||

| All the weldings of net wires of walls are provided at 360°, this not only for a qualitative need but especially for sensitivity to security. The loose wires with a roll container in use at full load represent one of the most dangerous situations of danger to the safety of workers. |  |

|

| Since 2003, on the CeDiROLL is printed indelibly our trademark and date of production on 12 different points on the base and walls (the date of production on 6 different points), in order to allow the traceability of the product, but above all it allows to our users to see the renowned quality and durability. |  |

|

|

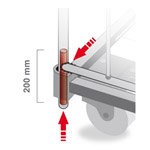

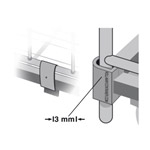

Since we start producing, our roll containers have a reinforced core which is inserted into the final part of walls; these internal reinforcements, added and fixed with punching, guarantee the seal and maintain the sizes and wall’s shape. The wall’s cross is printed with shaped ends housing in order to join perfectly to the wall’s frame and then with a weld line is able to ensure the best seal. The lower part of the wall is in fact the point that suffers stressed of load contained in a roll container; our constructive solution has been tested and then confirmed thanks to 250,000 units produced. |

|

|

| The coupling springs of the wall, at the base, are printed in harmonic steel, treated by specific annealings, and only afterwards undergo the galvanizing treatment; this is to ensure a superior elasticity that allows the perfect closing of hooking and release in time, important in applications involving disassembly and reassembly, even daily. |  |

|

| In 2009 we introduced the drain holes for the natural draining of rainwater during the phases of inactivity, in order to avoid unpleasant and unhygienic backups during overturning phases in the mounting |  |

|

Plastic bins

Security and environment

Bins

Bunded pallets in polyethylene or steel

Drum dispensing and supports

Outside storage containers and cabients in steel and polyethylene

Metal sheds, portacabins and shipping containers, portable toilets

Metal shelving for the storage of drums, IBC and containers

Gas bottle storage depots and cabinets

Safety barriers and jersey barriers

Shop fittings and workshop storage

Trucks and warehouse trolleys

Metal containers

Steel containers and laundry trolleys

Wire containers

Dumping bins and tipping skips

Sheet metal industrial containers

Mesh industrial containers

Drop bottom skips and bins

Open fronted metal containers

Metal storage boxes and bins

Crane boat skips and concrete buckets for building

Site boxes for tools

Insulated containers

Packaging and shipping supplies

Pallets

Wheels and castors

Lifting equipment and loading

Machine tools and processing machinery

Power tools and hand tools

Tool sets and assortments

Tool kits in cases and boxes

Wrenches and spanners

Screwdrivers

Male-end wrenches

Bits and bit holders

Sockets and accessories

Torque wrenches and multipliers

Pliers, wire cutters and nippers

Drills, impact drivers and pneumatic tools

Punches, drift, pin and centre punches

Car jacks, car and motorcycle lifters

Car battery chargers and starters

Cable reels and hose reels

Rollawaycontainer.com srl

Via Luigi Cadorna, 56 - 58

30020 Fossalta di Piave - Venezia (Italia)

Tel. +39 421 67358

Fax +39 421 306462

[email protected]

Copyright © 2014 - Rollawaycontainer.com srl - CF/N.Iscr.Reg Imp VE/PI 03394420271 - REA n° 304615

Cap. Soc. 20.000 € i.v. - E-mail: [email protected]