You have no items in your shopping cart.

Rollawaycontainer.com srl

Via Luigi Cadorna, 56 - 58

30020 Fossalta di Piave - Venezia (Italia)

Tel. +39 421 67358

Fax +39 421 306462

[email protected]

This website uses cookies to improve users' browsing experience and to gather information on their use of the website. We also use third-party profiling cookies to send advertising messages in line with user preferences. You can learn more and manage your choice at any time by visiting our cookies policy.

| Code | RF050 | RF050I | RF050U | |||

| Variable spindle speed | (8) 115 ÷ 1750 rpm | (2) 100 ÷ 600 |350 ÷ 2000 rpm | (8) 115 ÷ 1750 rpm | |||

| Horizontal spindle speeds | - | - | (9) 60 ÷ 1350 rpm | |||

| Engine | 400 V 50 Hz 0,85 - 1,5 kW | 400 V 50 Hz 2,2 kW | 400 V 50 Hz 0.85 - 1.5 kW | |||

| Common features to all codes | ||||||

| Face milling cutter max | 100 | |||||

| End milling cutter max mm | 32 | |||||

| Max drilling capacity on cast iron with pre-drilling hole mm | 50 | |||||

| Max drilling capacity on steel with pre-drilling hole (s235jr) mm | 30 | |||||

| Spindle taper | ISO40 DIN2080 | |||||

| Quill mm | 90 | |||||

| Vertical head rotation | ± 45° | |||||

| Head body rotation | ± 180° | |||||

| Spindle travel mm | 120 | |||||

| Table movement motor | 400V 50Hz 0.325 KW | |||||

| Base dimensions mm | 510 x 900 | |||||

| Cooling pump | 400V 50 Hz 0.4 KW | |||||

| Distance between spindle nose and table mm | 60 - 360 | |||||

| Distance spindle axis - column surface mm | 250 - 650 | |||||

| Table dimensions mm | 800 x 240 | |||||

| Longitudinal axis mm | 380 | |||||

| Cross axis mm | 220 | |||||

| Slot mm | 14 | |||||

| Maximum capacity kg | 300 | |||||

| Dimensions mm | 1380x1200x2100 | |||||

| Weight kg | 930 | |||||

| Standard | Base with chip tray, coolant system, LED lamp, 3 Axis DRO, machine vise 160mm, ISO40 spindle with ER32 8 Pcs, reduction sleeve ISO40 CM 3, key type drill chuck 3-16mm B18, drill arbor ISO40 B18, 2 horizontal milling arbors (only in RF050U)*, 2 M16 draw bars for ISO40 spindle, motorized longitudinal axis with gears with quick movements, round table flyers with neutral function | |||||

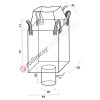

Tubular big bag with discharge spout and skirt

From €5.16 (ex. VAT)

Universal bench for drilling machines Fervi 0599 capacity 400 kg

From €270.60 (ex. VAT)

Locker wardrobe space saver metal 2 tier nest of 2 with lock monoblock Armet

From €201.21 (ex. VAT)

Vertical drilling machine Fervi F060

From €11,622.87 (ex. VAT)

Bench drilling machine Fervi T046 with drive belt

From €2,277.15 (ex. VAT)

Floor drilling machine Fervi T073 with drive belt

From €5,055.90 (ex. VAT)

Floor drilling machine Fervi T052 with drive belt

From €2,628.84 (ex. VAT)

Plastic bins

Security and environment

Bins

Bunded pallets in polyethylene or steel

Drum dispensing and supports

Outside storage containers and cabients in steel and polyethylene

Metal sheds, portacabins and shipping containers, portable toilets

Metal shelving for the storage of drums, IBC and containers

Gas bottle storage depots and cabinets

Safety barriers and jersey barriers

Shop fittings and workshop storage

Trucks and warehouse trolleys

Metal containers

Steel containers and laundry trolleys

Wire containers

Dumping bins and tipping skips

Sheet metal industrial containers

Mesh industrial containers

Drop bottom skips and bins

Open fronted metal containers

Metal storage boxes and bins

Crane boat skips and concrete buckets for building

Site boxes for tools

Insulated containers

Packaging and shipping supplies

Pallets

Wheels and castors

Lifting equipment and loading

Machine tools and processing machinery

Power tools and hand tools

Tool sets and assortments

Tool kits in cases and boxes

Wrenches and spanners

Screwdrivers

Male-end wrenches

Bits and bit holders

Sockets and accessories

Torque wrenches and multipliers

Pliers, wire cutters and nippers

Drills, impact drivers and pneumatic tools

Punches, drift, pin and centre punches

Car jacks, car and motorcycle lifters

Car battery chargers and starters

Cable reels and hose reels

Tubular big bag with discharge spout and skirt

From €5.16 (ex. VAT)

Universal bench for drilling machines Fervi 0599 capacity 400 kg

From €270.60 (ex. VAT)

Locker wardrobe space saver metal 2 tier nest of 2 with lock monoblock Armet

From €201.21 (ex. VAT)

Rollawaycontainer.com srl

Via Luigi Cadorna, 56 - 58

30020 Fossalta di Piave - Venezia (Italia)

Tel. +39 421 67358

Fax +39 421 306462

[email protected]

Copyright © 2014 - Rollawaycontainer.com srl - CF/N.Iscr.Reg Imp VE/PI 03394420271 - REA n° 304615

Cap. Soc. 20.000 € i.v. - E-mail: [email protected]